HyperLysis

What is HyperLysis?

HyperLysis™ is the World's fastest bead beating based sample homogenization technology.

HyperLysing is, for all intents and purposes, the point at which optimized lysing occurs. We call it HyperLysing to separate it from the lysing performed by other machines, which for the most part, provide for inefficient forms of lysing. In comparison to those machines, the RotaPrep machines look like they perform an advanced form of lysing, and to the lysing world, this optimized lysing does indeed look like something new and exciting.

In order to fully understand the true value of the HyperLysis technology, it is useful to have an understanding of what has up to this point been considered to be conventional lysing.

Why is this Something New?

The homogenizers that have traditionally been on the market evolved from the early days of DNA analysis, and since that time, the vast majority of the machines have simply been either copies of something already existing, or they are marginal improvements of what has come before.

It is fairly simple to look back now and see that no real analysis was done to develop an homogenizer with optimal lysing. The reasons for that are unknown, however, the most likely explanation would be that building a machine to deliver the proper movement is not a simple one. Or at least, it required outside of the box thinking to fashion it.

Most of the machines that are designed primarily for the 2 ml tubes seem to have their inspiration from a vortexer, which was how many labs were able to lyse the cells early on in the new world of DNA analysis.

The Limits of Conventional Bead Beating Homogenizers

Most bead-beating homogenizers on the market fall into two basic categories:

- Tube homogenizers, designed for 2 mL tubes (sometimes adapted for larger tubes), and

- Plate homogenizers, built primarily for 96-well deep-well plates.

While their capacities differ, both rely on nearly identical mechanical principles. For the plate homogenizers, a motor drives a tube or plate holder that oscillates linearly along the long axis of the tube typically no more than an inch of total displacement. In each cycle, the mechanism must accelerate, stop, and reverse direction, consuming considerable energy. See Figure 1. Examples of such products include the FastPrep-96, Tissue Lyser LT, HG-600, and the Geno/Grinder.

Figure 1

The tube homogenizers mostly use a swirling, figure 8, motion that causes the matrix/sample mixture to be suspended mostly in the center of the tube with occasional impacts at the top and bottom of the tube. See Figure 2. Examples include the FastPrep-24, FastPrep-120, Bead Blaster-24, Bead Ruptor, Mini-beadbeater-96, Mini-Beadbeater-16, and the Precellys.

This motion is basically a mixing motion. The tube figure 8 motion likely came from the motion of a vortex mixer, which was an early way to prepare DNA samples, and the linear motion from just what one might expect from shaking a can of spray paint to thoroughly mix it.

By making those motions aggressive enough, the harder matrix material would eventually be able to destroy the softer biological material. While usable, aggressive mixing is not as efficient or effective for complete lysing.

Figure 2

Another common format for tubes and plate homogenizers is the angular planar oscillator. The problem with this format is that for an array of tubes, the tube in the outer radius will experience more travel and higher acceleration than a tube at the inner radius. This requires the remedial action of stopping in the middle of a run to reposition the tubes. See Figure 3. Examples include the TissueLyser iii, Bead Ruptor 96, and BeadBlaster 96.

Another common format for tubes and plate homogenizers is the angular planar oscillator. The problem with this format is that for an array of tubes, the tube in the outer radius will experience more travel and higher acceleration than a tube at the inner radius. This requires the remedial action of stopping in the middle of a run to reposition the tubes. See Figure 3. Examples include the TissueLyser iii, Bead Ruptor 96, and BeadBlaster 96.

Figure 3

That back-and-forth limitation also constrains the motion of the bead matrix inside the tubes. The beads can only travel a short distance, striking the sample repeatedly in the same confined region rather than along the full interior of the tube. The result is incomplete, inefficient homogenization.

How Did HyperLysing Come About?

HyperLysing arose because of two main factors. The first was to just look at the traditional homogenizers and wonder why they would limit the motion of the matrices in the tubes.

That question was fairly easily answered by recognizing that they were based on motions that made the full length of the tube motion a near impossibility. So then the second question was, what motion would do that?

It took some time, and it took a lot of effort, but here at RotaPrep we found out what that would be. And like many things, once you see the solution, it makes you wonder why you never saw it before.

The early application of HyperLysing was introduced in the MonoLyser. The results there were quite dramatic. Lysing of most materials can be done in a matter of seconds.

But the MonoLyser was designed as a portable device and was not scalable in form to be an adequate bench top device for larger numbers of tubes.

After more inspiration and effort, the PolyLyser came into being, and once again, with HyperLysing, samples can be lysed in a matter of seconds.

The MegaLyser followed along shortly after, using the exact same mechanisms configured primarily for the 96 well plate market. It can, however, be used with virtually any other tube size.

The HyperLysing Motion

So, what is the optimal lysing motion?

Once understood, the answer is quite obvious. The bead matrix should traverse the entire internal length of the tube, from one end to the other, colliding with every part of the sample. That complete travel maximizes energy transfer, ensures uniform exposure, and effectively turns the tube itself into an active grinding surface.

Of course, creating that motion is not simple, and it requires an innovative and creative mind to bring it about. Through extensive experimentation, we developed a patented mechanism that makes this ideal motion practical. Rather than linear reciprocation, it uses continuous rotary motion that displaces each tube approximately two inches (50mm) — the full length of a standard 2 mL tube.

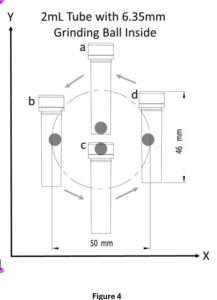

In this motion, the tube moves in a smooth circular path. Figure 4 depicts the motion of tube tracing a circular route via sequential positions a, b, c, and d. The motion is continuous, not back-and-forth, so it requires far less energy while driving the internal bead matrix to fully traverse the tube from end to end with every revolution. The change of direction of the matrix/sample mixture at the top and bottom extremities of the tube maximize impacts and maximize lysing-action. In addition, the circular trajectory of the tube causes the matrix and sample mixture to be forced against the walls of the tube resulting in an increased incidence of collisions as they travel along the long axis of the tube. The linear motion of most 96-deep well bead beaters does not do this.

Figure 4

This new full-length (of the tube) motion achieves complete lysis in seconds.

Figure 5

How Important is HyperLysing in Choosing a Homogenizer?

The short answer? Very.

RotaPrep homogenizers with HyperLysing are the ONLY machines on the market anywhere in the world that ar able to reach the threshold of optimal lysing. Yes, other machines can work around their inefficiencies to get results in many cases, but why settle for that?

This isn’t a case where RotaPrep homogenizers are more expensive because they are the best, so one needn’tt feel pressured by cost concerns. The other homogenizers that are less efficient actually have to add extra cost to their machines in an effort to overcome their inefficiencies. What is the point in paying for that?

The efficiency of HyperLysing saves the user time with shorter run cycles. And that has multiple benefits. It saves time just as an act of saving time. It also saves on wear and tear on the machine. So when compared to conventional machines, you are putting perhaps 20% or less of wear and tear on the RotaPrep homogenizers with each run. Down the road, that could be a significant savings. And lastly, the greater efficiency in lysing gives the added benefit of less heat transferred to the sample.

Also, All RotaPrep machines — MonoLyser, PolyLyser, and MegaLyser — share the same fundamental HyperLysing motion. That means a 2 mL tube run in a PolyLyser experiences the identical internal bead dynamics as a tube processed within a plate inside the MegaLyser. This yields a consistent, reproducible homogenization across every format.

The real question one must ask, is why would anyone consider buying any homogenizer the doesn’t employ HyperLysing?